Digital Motor Checker-28N

Product Details:

- Product Type Digital Motor Checker-28N

- Material SS

- Color White

- Click to View more

Digital Motor Checker-28N Product Specifications

- White

- Digital Motor Checker-28N

- SS

Product Description

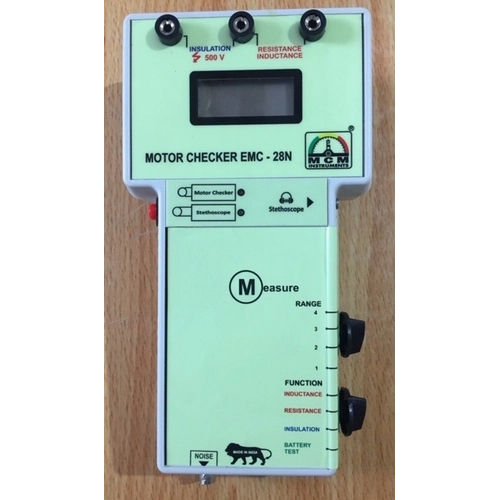

Digital Motor Checker EMC-28N

Features:

Insulation Resistance (IR) Measurement

Detects blow holes or cracks in the Rotor bar without dismantling the rotor

Inductance Measurement of the winding

Low resistance measurement of the winding

Identifies open and short circuits / loose Connections in a winding coil

Identifies inter tern shorts

Simple operation accurate & quick assessment of motor condition.

Noise (Mechanical sounds detection) for easy location of machinery noise in industrial Environments

Very handy

Battery Condition of Instrument

Low battery Indication

Light Weight

PREDICTIVE MAINTENANCE: Regular testing can identify developing faults before a failure occurs. All measurement data can be trended for predictive maintenance condition monitoring. By making proactive repairs and eliminating unscheduled down- time, plant productivity is greatly improved. EMC-28N is a Digital portable diagnostic tool for Electrical Engineer and is used for quick on - site checks of electric motor and other three - phase machines.

A reduction in machine performance, such as inefficient operation or tripping of overloads, may indicate mechanical or electrical faults. If the fault is electrical the EMC-28N will immediately detects it, without dismantling the equipment. The instrument has three separate operating modes to measure different types of faults like fully insulation, open circuits / loose connections, short circuits, Ground faults and rotor defects. Motor insulation is tested

with a high voltage at 500VDC supplied by the instrument.

NOISE: (Electronic stethoscope) Listening to machine sounds in order to determine the probable source of abnormal noise is one of the most widely used methods in maintenance departments across all branches of industry. Our electronic stethoscope is a practical and easy-to-use listening device that helps pinpoint the source of mechanical noise in a broad range of applications. Bearing condition, gear and pump noise, and electric relay operation are just a few of the many sounds which can be identified, amplified, and assessed.

Motor Checker EMC-28N finds the faults you can't see with any other hand held instrument Turn -to-turn , coil-to-coil and phase-to-phase faults

Open phase Burned or contaminated winding Poor Connections, Broken / Cracked rotor bars Grounded windings, Cable faults., Mechanical Noise of Machines / Bearing, gear and pump noise

Display: 3 1/2 LCD Temp. Operating Range: 0- 55oC Size: 237x131x45 Weight: 700gms

Power: 1.5V x 6 AA size cells Enclosure: Moulded in high impact ABS.

Standard Supply:

- Motor Checker EMC-28N

- Test Leads - 1set

- Noise Probe with Tip

- Head Phone

- Batteries - 6nos Manual

- Calibration Report & Warranty / Guarantee Certificate

- Carry Case

Frequently Asked Questions

Check the electric motor's voltage with a multimeter or an ohmmeter. The motor is probably broken if there is no resistance or unequal resistance. Make sure the bearings can spin freely by inspecting them. Lubricate them if they are unable to.

How do you check for motor problems?

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free